The crusher is mainly used for the crushing or breaking of large rocks in the mining process. With the development of crushers, the overall process of the mining industry has been improved, and the crushers as the core equipment in large mining processing. The crusher is applied to primary, secondary and fine crushing based on the size of material. The development of the crusher is based on the continuous improvement of the application, and the performance is also continuously improved to meet the demand to a greater extent.

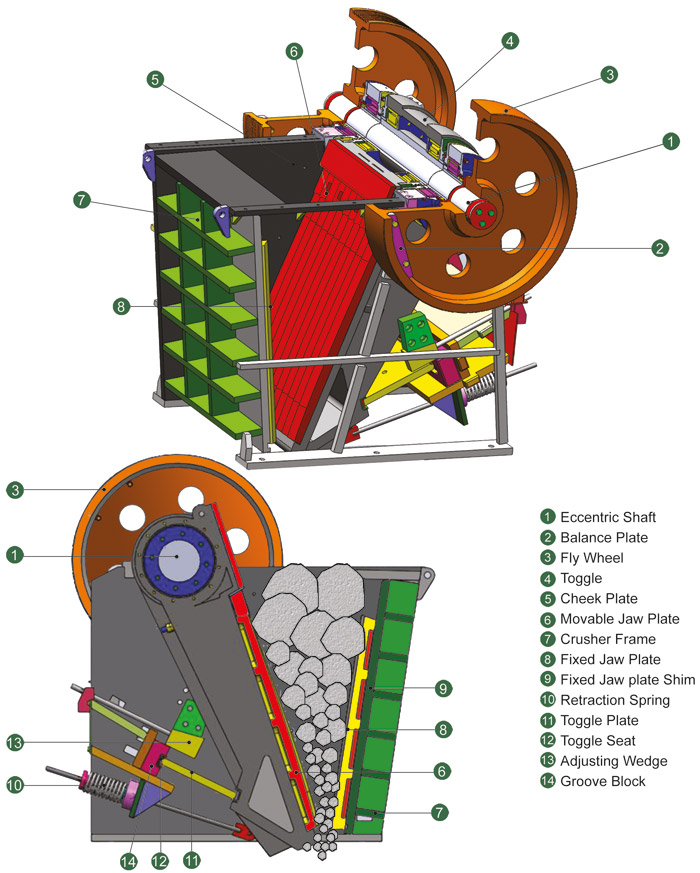

In the 1980s, the crusher used two jaws to squeeze and break the material as a primary and secondary crushing, it only made a simple arc swings while working, so named as Simplified Swing Jaw Crusher. If it also moved up and down while swinging, so named it as Complex Swing Jaw Crusher. The jaw crusher is widely used in the mining, smelting, construction materials, road, railway, water conservancy and chemical industries, the jaw crusher is usually applied to the material with a compressive strength of less than 320 MPa. Due to the development of the requirements, in order to avoid the impact of production caused by manitenance, hydraulic devices can also be applied to achieve adjustment. Some jaw crushers also use hydraulic transmission to drive the swing jaws to crush. These two types of jaw crushers with hydraulic transmissions are often referred to as hydraulic jaw crushers.

In the early 1970s, the gyratory crusher’s hammer gyrate in the cone cavity to crushing, splitting and bending of the material, as primary crushing of high hardness of ore or rock. The upper end of the main shaft equipped with the crushing hammer is supported by the bushing in the middle of the arm, and the lower end is placed in the eccentric hole of the bushing.

The uniformity of the discharge material size of the secondary and tertiary crushing operations is generally higher than that required for the primary crushing. Therefore, a parallel section must be applied under the crushing chamber. Also, the speed of the crushing cone need to be faster so that the material can be crushed more than one time is in the parallel section. The discharge opening of the cone crusher is so small, and the non-crushed material mixed into the opening is more likely to cause failure. Due to the discharge material size of secondary and tertiary crushing, the discharge opening should be adjusted in time after the liner is worn, so the settings and adjustment of the cone crusher is more necessary than primary crushing.

At the same time, the hammer crusher and the impact crusher continue to evolve, especially the impact crusher has a larger crushing ratio and fully utilize the impact energy of the entire rotor. However, the hammer worn easily, it is also limited in the application of hard material operation. It is usually used for primary crushing, secondary crushing or fine crushing of limestone, coal, calcium carbide, quartz, dolomite, iron sulfide ore, gypsum and chemical raw materials which are medium hardness and low brittleness.

The crusher is widely used in many industries such as mining, smelting, building materials, roads, railways, water conservancy and chemical industries. At present, the commonly used crushing machinery such as jaw crusher, impact crusher, air-blast breaker, hammer crusher, vertical shaft impact crusher, roller crusher, composite crusher for construction materials, bricks, coal, metallurgy, mining, electric power, light industry for crushing coal, shale, coal slag, carbon, lime, cement, sorghum and medium-hard brittle materials.